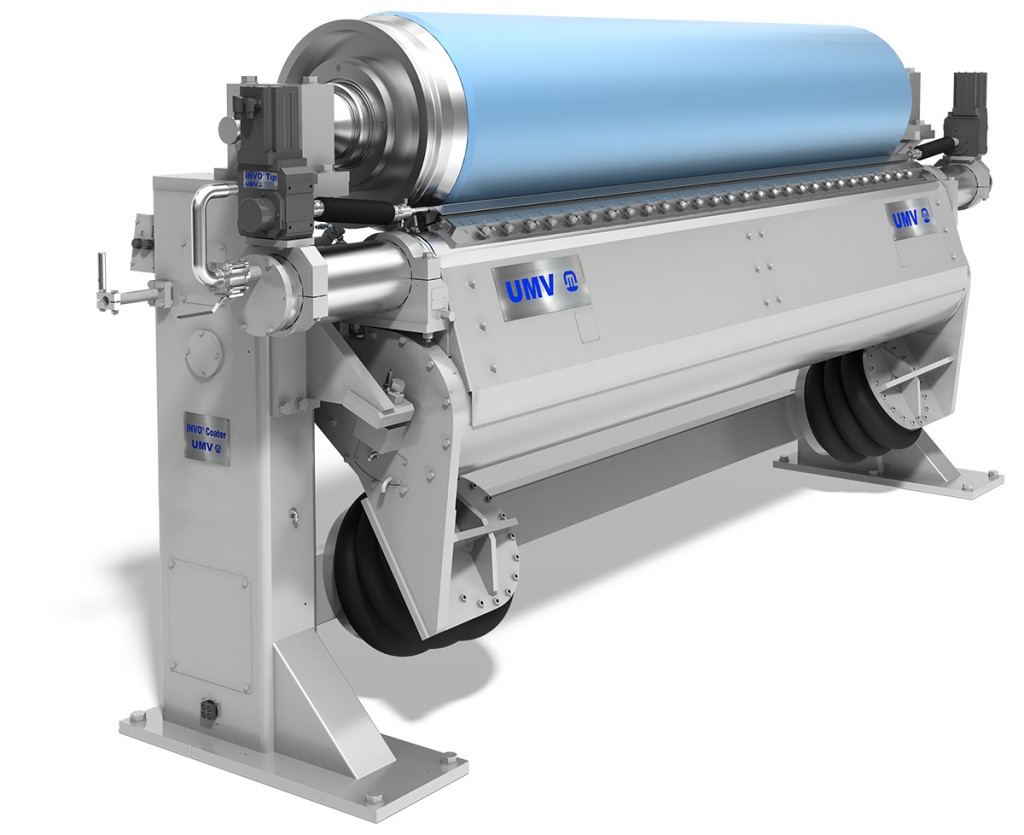

INVO® Coater

This is the Unique Zero Dwell Coater

INVO® Coater from UMV is one of the best inventions since the start of coating and sizing. It follows the innovative tradition of UMV with several proven state-of-the-art technologies in the offering, such as the INVO® Tip metering element and the ABC™ Coater.

INVO® Coater from UMV is one of the best inventions since the start of coating and sizing. It follows the innovative tradition of UMV with several proven state-of-the-art technologies in the offering, such as the INVO® Tip metering element and the ABC™ Coater.

The INVO® Coater is a compact combination of a Jet Coating Applicator with a system for conventional rod or INVO® Tip metering. In this way, the application and metering of the coating color takes place with minimum dwell time, which offers the possibility to run with high solids in both starch and coating color applications.

The applied media stays on the surface of the sheet and reduces coat weight needs while giving you excellent coverage.

The possibility to apply thin coating layers with a low wet amount makes this coater an excellent choice for barrier applications.

It can be used for both front- and reverse side treatment in numerous combinations and set-ups.

Can be equipped with either a manual or an Automatic Profiling System. Because of its design, it is perfectly suited for retrofits, which often have space limitations.

The media is applied and metered off in one step, the dwell time is nearly zero.

Design

Features

- Compact

- Modular

- Versatile

Benefits

- Can easily be installed in a confined space

- Several machines can be installed in sequence, allowing for a larger number of coating layers within the same space

UMV has set a New Standard with this Zero Dwell Coater

Mill Case Examples:

- Replacing Airknife coaters

- Reverse side treatment, board production

- Top side treatment, board production

- Multiple barrier layer coating

- Coating of low basis weight/weak web

- Vortex free, zero-dwell coater

Zero Dwell Application

Features

- Base paper retains its strength during the coating operation

- Surface-located treatment

- Higher solids for same coat weight

Benefits

- Excellent runnability

- Excellent coverage and possibility to reduce coat weight

- Energy saving

- Excellent barrier coater

- Uniform application without any vortex problems